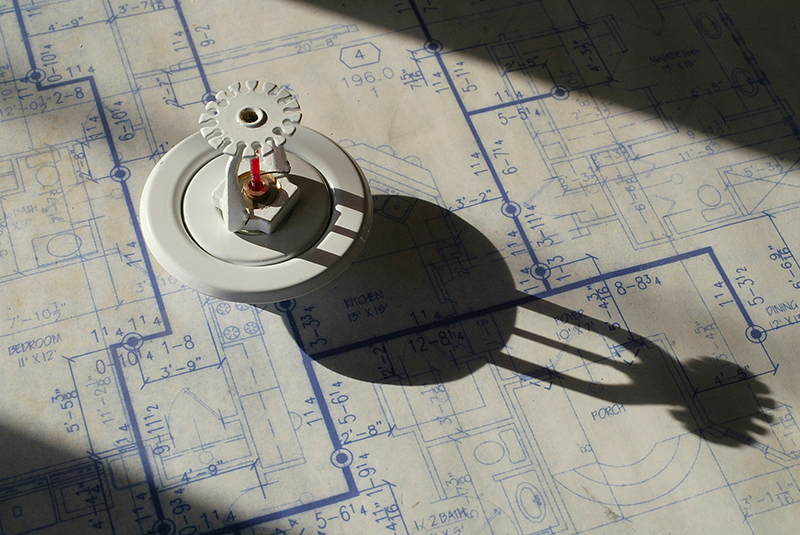

A fire sprinkler system designed by Imperial Fire Protection will give you the assurance and peace of mind that when a fire breaks out, your most valuable assets will be protected. From Residential to Commercial design, fire sprinkler systems can save lives and prevent financial, physical, and emotional damage. Simply put, a well-designed sprinkler system protects people. Fire sprinkler design is a complicated process but trust the experts at Imperial Fire Protection to get the job done right with honesty and integrity.

How IFP Helps You Protect Your People

- Safety is our #1 goal

- Broad-spectrum of project experience

- Experts in design with 21 years of experience

- Residential and commercial design

- Highly skilled licensed professionals

- We offer long-term solutions you can trust

- Cost-effective design without cutting corners

- Unparalleled attention to detail

Need a fire sprinkler system designed?

Schedule a consultation today.

Ways Our Approach to Design is Unique

Safety is our #1 goal…

We are honest in our recommendations and will never advise you to do something that compromises safety when it comes to your sprinkler system. The bottom line is we design with your safety in mind.

Experts in design with 21 years of experience…

As experts in the industry, when we design your commercial or residential fire sprinkler systems, you can trust our experience and have confidence you will be getting the best fire protection system available.

No project is too big or small…

We have worked on projects of all sizes ranging from simple to the most complex. From residential fire sprinkler systems, industrial to commercial projects such as churches, schools, hospitals, and office spaces, we design fire sprinklers to fit your unique needs and protect your people.

Highly skilled licensed professionals…

Fire sprinkler design is a complex process. However, you can have confidence that your fire sprinkler system will be designed by highly trained licensed professionals you can trust at Imperial Fire Protection.

We offer long-term solutions you can trust…

We design your fire sprinkler system with the future in mind. Your sprinkler system will meet your fire protection needs both now and in the future with quality sprinkler heads built to withstand the test of time.

Cost-effective design without cutting corners…

Our fire sprinkler systems are designed with quality workmanship you can trust. We build the most cost-effective fire sprinkler systems on the market while maintaining attention to detail and never cutting corners.

Unparalleled attention to detail…

Imperial Fire Protection prides itself on designing fire sprinkler systems that meet the unique needs of our clients. Our meticulous attention to every detail in both understanding your needs and implementing them in your sprinkler system is what sets us apart.

Are you ready to take the next step? Schedule a consultation today.

Learn More About Fire Sprinkler Design

Who designs fire sprinkler systems?

When well-engineered and up to code, fire sprinkler systems save lives and property. A licensed professional engineer or architect will check the water supply, identify building needs, and layout pipes and sprinklers to comply with state requirements. Different states and municipalities may have additional requirements from the NFPA 13. NFPA 13 is the Standard for the Installation of Sprinkler Systems and is the document adopted by jurisdictions that govern commercial fire sprinkler system design. Fire sprinkler system design requires a professional to ensure the job is done right.

What makes a good system design?

Fire sprinkler design takes expertise and meticulous planning. When designing a fire sprinkler system, several factors must be considered. Fire sprinkler system design begins with water and determining whether enough of it is ready to control a fire. NFPA 13 requires an automatic water supply, meaning that the water will flow through sprinkler heads without any human intervention. Many possible sources can include city water, ponds, rivers, reservoirs, water tanks, pressure tanks, gravity tanks, or water towers. However, municipal waterworks is the standard supply in most cases.

Sufficient capacity for fire control is the number one priority no matter the source. The factors that determine capacity include the flow rate (in gallons per minute, GPM), pressure (in pounds per square inch, PSI), and duration (how long it can maintain the required pressure and flow). A flow test performed at nearby fire hydrants can determine the capacity for a municipal water supply.

A flow test requires at least two hydrants. First, a static pressure reading is taken at the first hydrant while neither hydrant is flowing water. Then, the second hydrant is opened wide, and another pressure reading is taken at the first hydrant. This is called the residual pressure reading, which tells us the amount of pressure that can push water through sprinkler heads (minus some losses). Finally, a pitot tool is used to measure the pressure of the water flowing from hydrant B.

After evaluating the water supply, a fire protection expert will determine what kind of sprinkler system the building needs. Next, they will identify the hazard level of the building and the protection required, followed by picking and laying out sprinkler heads. The last step will involve choosing and laying out the pipe. Including all of these details in the design process leads to well-engineered fire protection systems.

Are you ready to take the next step?

Schedule a consultation today.

Cost Considerations

Fire sprinkler systems vary in cost based on the size of fire sprinklers and the type you install. In general, here are the costs you can expect:

- For new construction projects: $1 to $2 per sprinklered square foot

- For retrofitting existing homes and businesses: $2 to $7 per sprinklered square foot

- For retrofitting high-rise buildings: $2 to $4 per sprinklered square foot

- For retrofitting historic buildings: Up to $10 per sprinklered square foot

Costs for your sprinkler installation may vary based on these factors:

- Pipe material: The most affordable type of piping is plastic. In order to keep costs down, you should use it wherever possible. You may need more expensive copper piping in some places, which will increase the installation cost.

- System features: It is common for most businesses to have access to the municipal water supply. A backflow preventer may be required to be installed if your system runs on an antifreeze solution. However, if your building gets water from a well or another private water source, your sprinkler system may require a water storage tank and booster pump. All of these things must be factored into the overall installation cost.

- System design: Standalone pipes with a dedicated water supply are used with most fire sprinklers. Pipes that are combined for domestic use and fire sprinklers are known as multipurpose. It is more expensive to install a standalone system than a multipurpose one when installed in new construction projects.

- Lifetime costs: When considering the costs to install a sprinkler system, you must view it as a long-term investment and consider many factors. Many insurance companies offer premium discounts for buildings with automatic fire sprinklers, and these savings should be factored in when determining the actual lifetime cost of the installation.

What is the standard pressure for a fire sprinkler?

Every sprinkler features a defined K-factor, which describes what proportion flow (GPM) it can produce at a given pressure (psi). Common K-factor values include 2.8, 5.6, and 8.0. The relationship between K-factor, flow (q), and pressure (p) is: K=q/√p

Designers often select a standard K-factor and check to ascertain if they will achieve the specified flow with the available pressure. If they cannot, they’ll choose another K-factor. Or, they’ll change something about the pipes to increase the available pressure. When designers layout a system on paper, they mark where the pipes will go and choose their size and material. Pipe selection affects hydraulic calculations, cost, corrosion resistance, and more.

The flow test only tells designers what proportion pressure is out there from the source and at the bottom of the system riser. They have less to figure with at the sprinkler heads due to head loss. Head loss is the loss of pressure due to resistance as fluid flows in pipes from its source to its destination.

Three sorts of resistance create head loss—gravity, friction, and turbulence. Designers can’t fight the consequences of gravity unless they use pumps; regardless of the pipes’ diameter, 0.433 psi is lost for each vertical foot. But they will select pipes, fittings, and devices to scale back the top loss from friction and turbulence.

The friction of water against the walls of the pipe fights against the pressure from the water system. The size of the friction force depends on three factors:

The rate of flow (q)

The empirical roughness of the pipes (C; small C means rough pipe)

The diameter of the pipes (d)

Designers use the Hazen-Williams formula (27.2.2.1.1) to calculate pressure loss per foot of pipe (p): p = (4.52Q1.85) ÷ (C1.85d4.87)

Selecting appropriate pipe materials and sizes helps minimize friction losses. For example, suppose hydraulic calculations reveal that a sprinkler head within the design area won’t get enough pressure to supply the planning density. In that case, the pipes’ size is often increased to scale back pressure loss.

Pipe material also affects pressure losses. C-value describes the roughness of the pipe, and pipe made from copper (C=150) or CPVC (C=150), for instance, is smoother than one made from unlined forged iron (C=100).

With pipe size and material, there are considerations aside from the hydraulic calculations. Up-front and long-term costs also are essential things to believe. Bigger pipe costs more, and copper pipe costs quite thermoplastics, for instance. In addition, nonmetallic pipes like CPVC have unique concerns regarding exposure and melting and may only be utilized in specific settings.

Balancing cost and function is a significant part of a sprinkler system designer’s job.

What are the components of sprinkler systems?

All fire sprinkler systems are often divided into two categories: wet systems and dry systems. Wet systems are characterized by a pipe network constantly maintained with pressurized water. A closed/un-activated sprinkler holds back water. Wet systems are the foremost common fire system, representing an estimated 85% of all installed systems. These systems are commonly installed in office, retail, warehouse, and commercial spaces.

In addition to the water supply, piping, and sprinklers, these systems have other required components: backflow prevention device, control valve, main drain, auxiliary drain, fire department connection, water flow alarm, and system air vent.

A backflow prevention device must be installed between the water source and, therefore, the fire system. A backflow preventer provides two main functions. The first function is keeping stagnant fire system water from flowing back to a municipal water system. The second function occurs during a fireplace event when the hearth department pumps water into the system via the hearth department connection to supplement the water system. In this scenario, the backflow preventer ensures that the supplemental water flows to the sprinklers and not back to the water system.

Control valves are often found in multiple locations on a fire sprinkler system. All control valves are required to be an ‘indicating’ type, meaning that they must provide a visual indication of the valve’s opened or closed status. Common types of indicating valves include Post Indicator, Outside Screw and Yoke and Butterfly Valves.

A main drain allows for water removal from the system and provides a forward flow test of the water system. The main drain must be sized according to the size of the riser.

An auxiliary drain must be provided in any situation where the pipe network changes directions and traps water in more than five gallons.

With few exceptions, every fire system is required to possess a fire department connection. Commonly referred to as the FDC, the fire department connection allows responding fire personnel to pump additional water into the sprinkler system, supplementing the existing water supply to the sprinklers and/or supporting firefighters entering the building.

Each sprinkler system zone must be equipped with a water flow detection device that will signal a water flow event. In a wet system, water flow is detected and signaled by an alarm check valve used in conjunction with a water motor gong or a paddle style flow switch monitored by the fire alarm system.

The fire safety industry now requires a means of venting trapped air from a wet system pipe network as it is filled with water. The 2016 edition of NFPA 13: Standard for the Installation of Sprinkler Systems added Section 7.1.5, which needs one air vent to be installed on each wet pipe system using metallic pipe. The air vent accomplishes two critical functions by ejecting trapped air from the pipe network as it is filled with water. First, the vent exhausts corrosive oxygen from the system, limiting the amount of corrosion that can take place in the system, which in turn reduces leaks and the need to replace piping. Second, removing gas from the pipe network eliminates nuisance waterflow alarms from paddle-style water flow switches. Nuisance alarms control when the water source pressure rises and compresses gas within the system. As water moves past the water flow switch, the paddle can be moved into the activated position. Depending on the dimensions of the wet system, the paddle is often held within the activated position long enough to beat the retard setting and activate an alarm condition on the fire alarm system.

Are you ready to take the next step?

Schedule a consultation today.